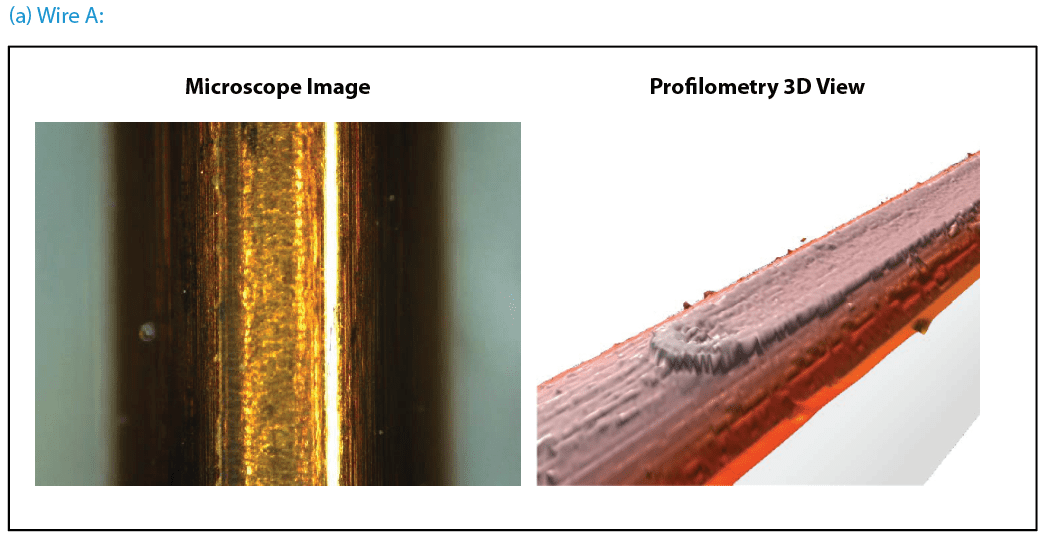

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

4.5 (608) · $ 30.00 · In stock

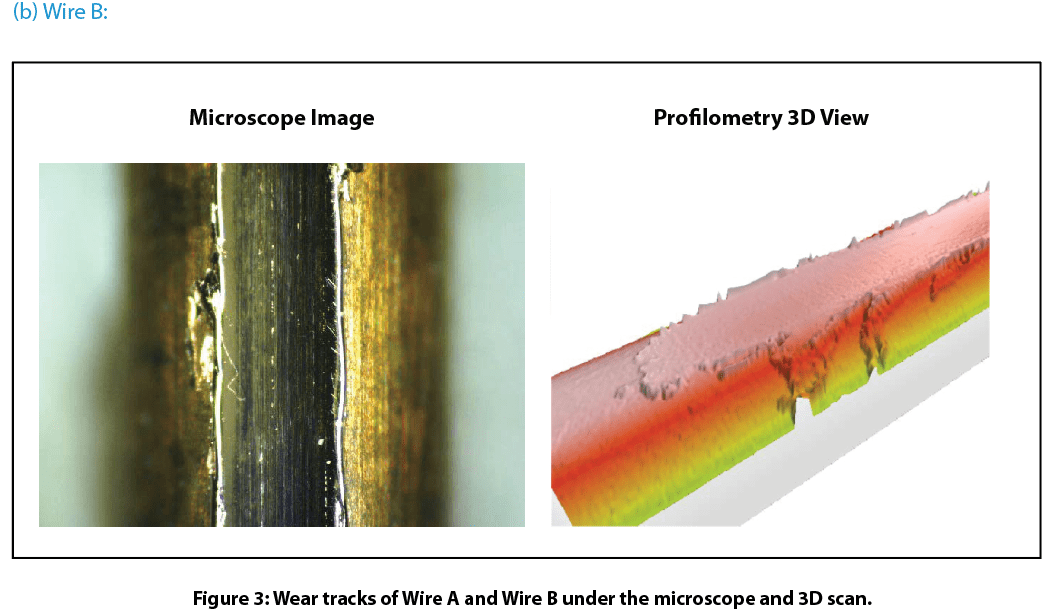

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

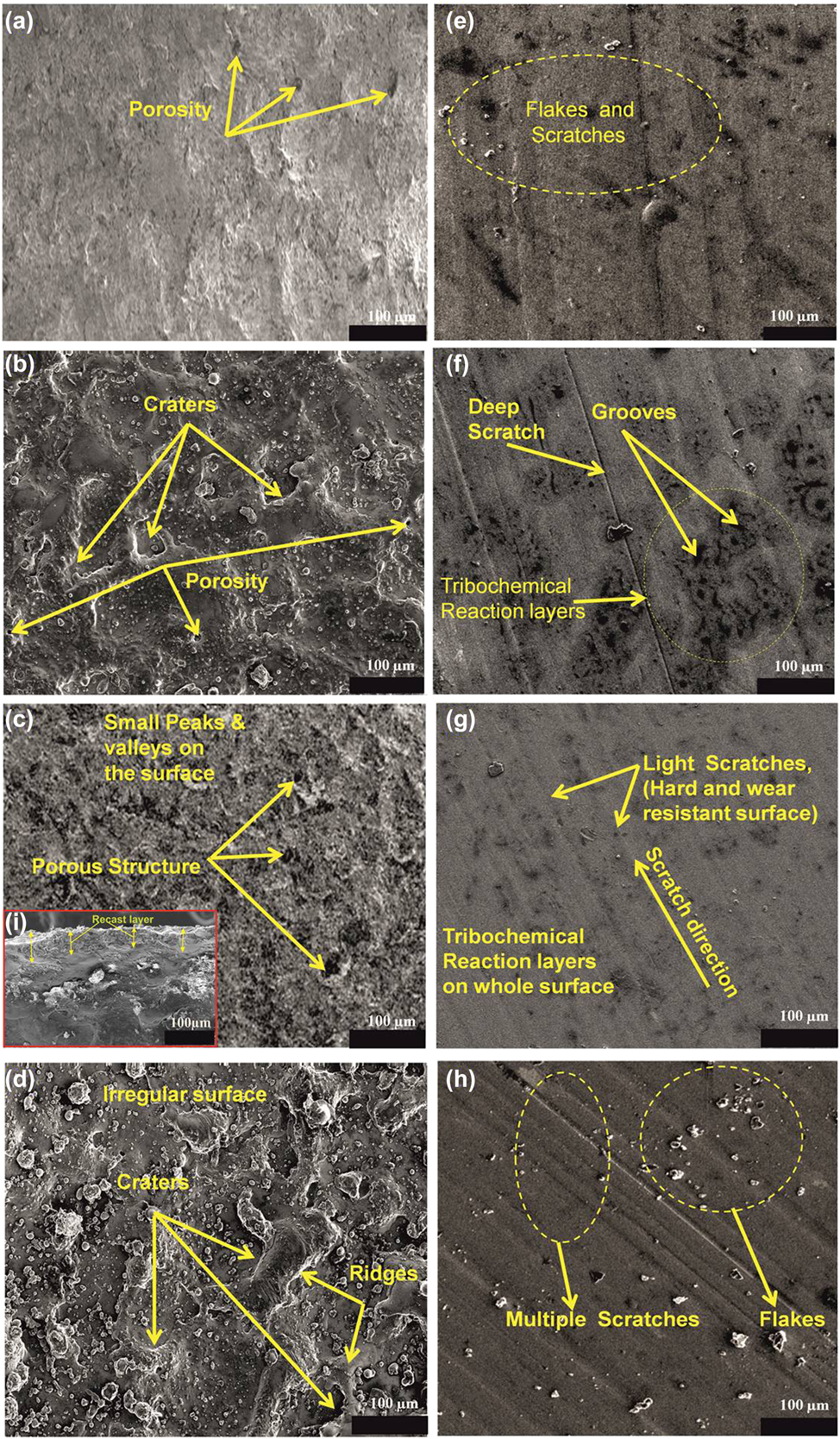

Potential of electrical discharge treatment to enhance the in vitro cytocompatibility and tribological performance of Co–Cr implant, Journal of Materials Research

The Role of Submerged Arc Welding in Heavy Fabrication - Red-D-Arc Red-D-Arc

Post-processing of additively manufactured metallic alloys – A review - ScienceDirect

🔥 【Nail tech must haves set for nail art】: You will get 1*15ml Base Coat+ 1*15ml Top Coat. It is normal for a base coat and color gel to remain a

modelones Gel Top Coat, 15ml No Wipe Clear Glossy Gel Base and Top Coat Set, Soak Off Nail Lamp Acid Free Base Top Gel Nail Polish Starter Kit

Influence of gelatin-TiO2-Al2O3 nanocomposite coatings on enhancement of wear and corrosion resistance of SKD11 steel - ScienceDirect

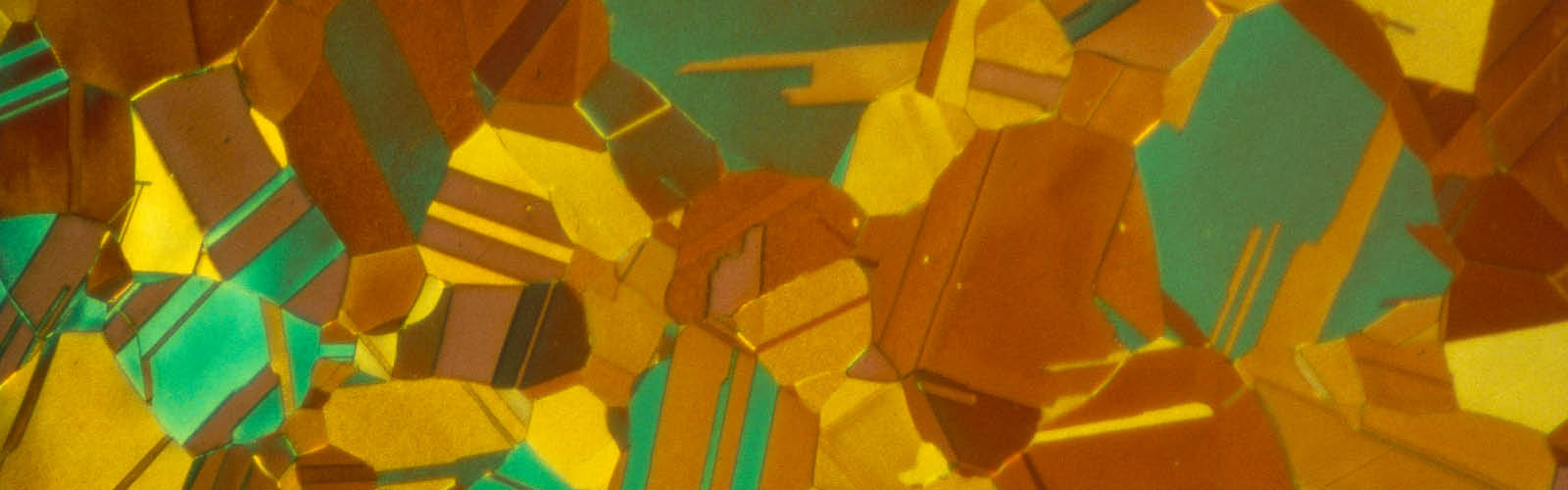

Metallography of copper and copper alloys insight

Dry sliding wear test on borided AISI 316L stainless steel under ball-on-flat configuration: A statistical analysis - ScienceDirect

High quality material: wire brushes set is made of stainless steel, durable, long service life on the toughest cleaning jobs. Practical tools: these

Rocaris Wire Buffing Wheel Brush Set, Wire Brush Set 1/8 Shank for Rotary Tools Accessories Polish Clean Tools, 120 Pack

Understanding the Different Types of Abrasion Testing - The TABER Test

Elcometer Surface Profile

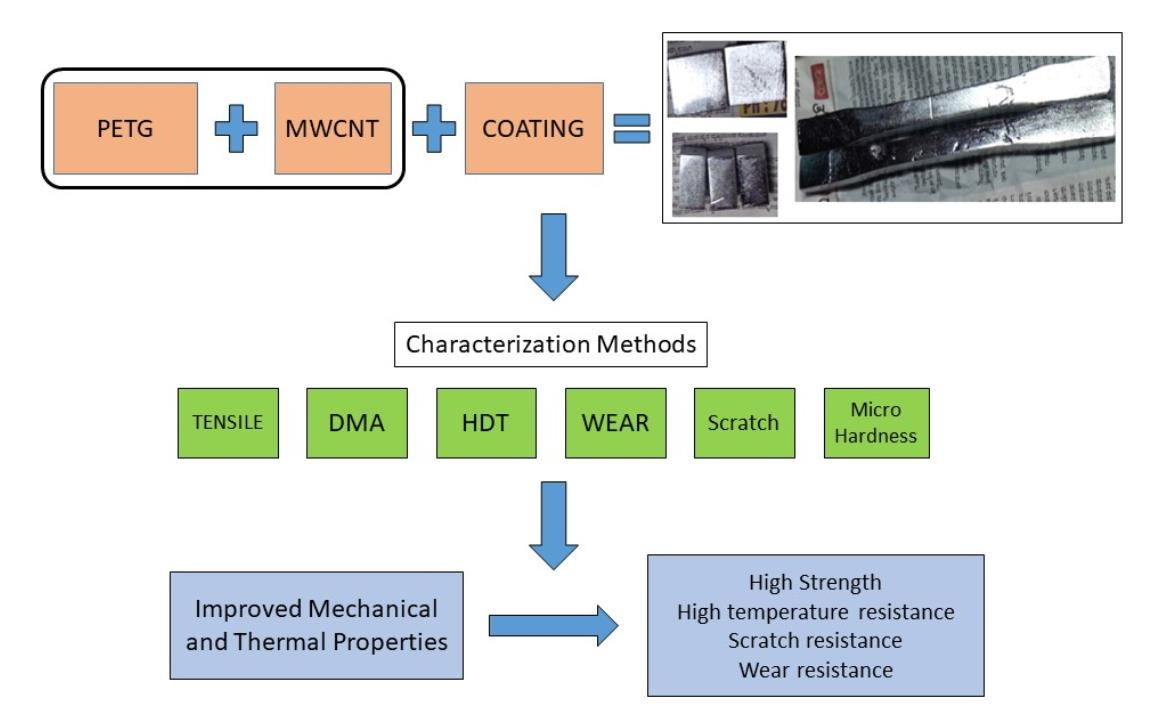

Polymers, Free Full-Text

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

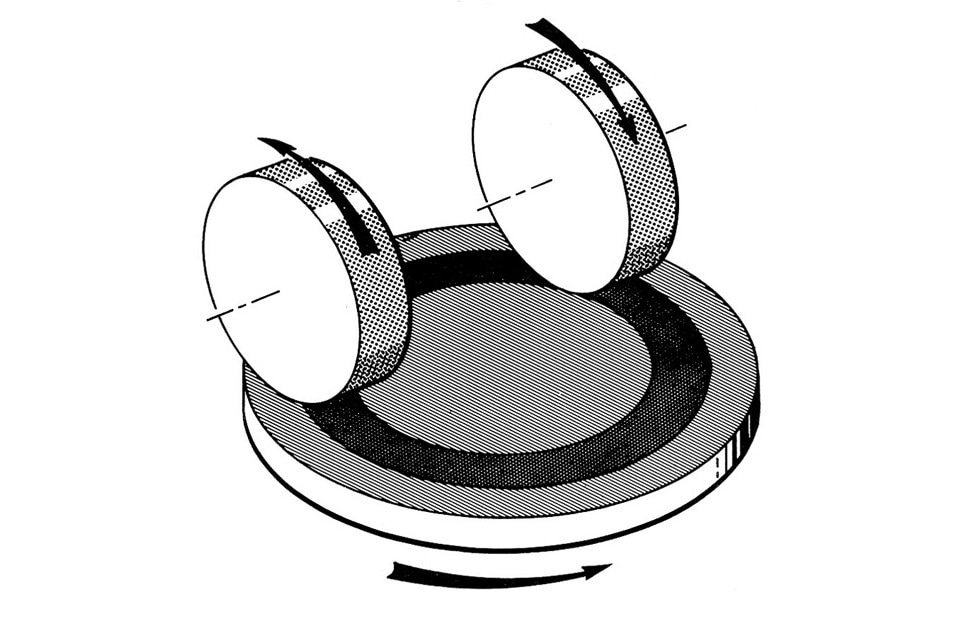

5 Grinding Considerations for Improving Surface Finish

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA