Why You Must Optimize Cooling and Venting in Plastic Injection Molds

4.5 (431) · $ 10.99 · In stock

Learn about the importance of optimized cooling and venting in plastic injection molds to avoid issues such as short shots, flash, or excess cycle times.

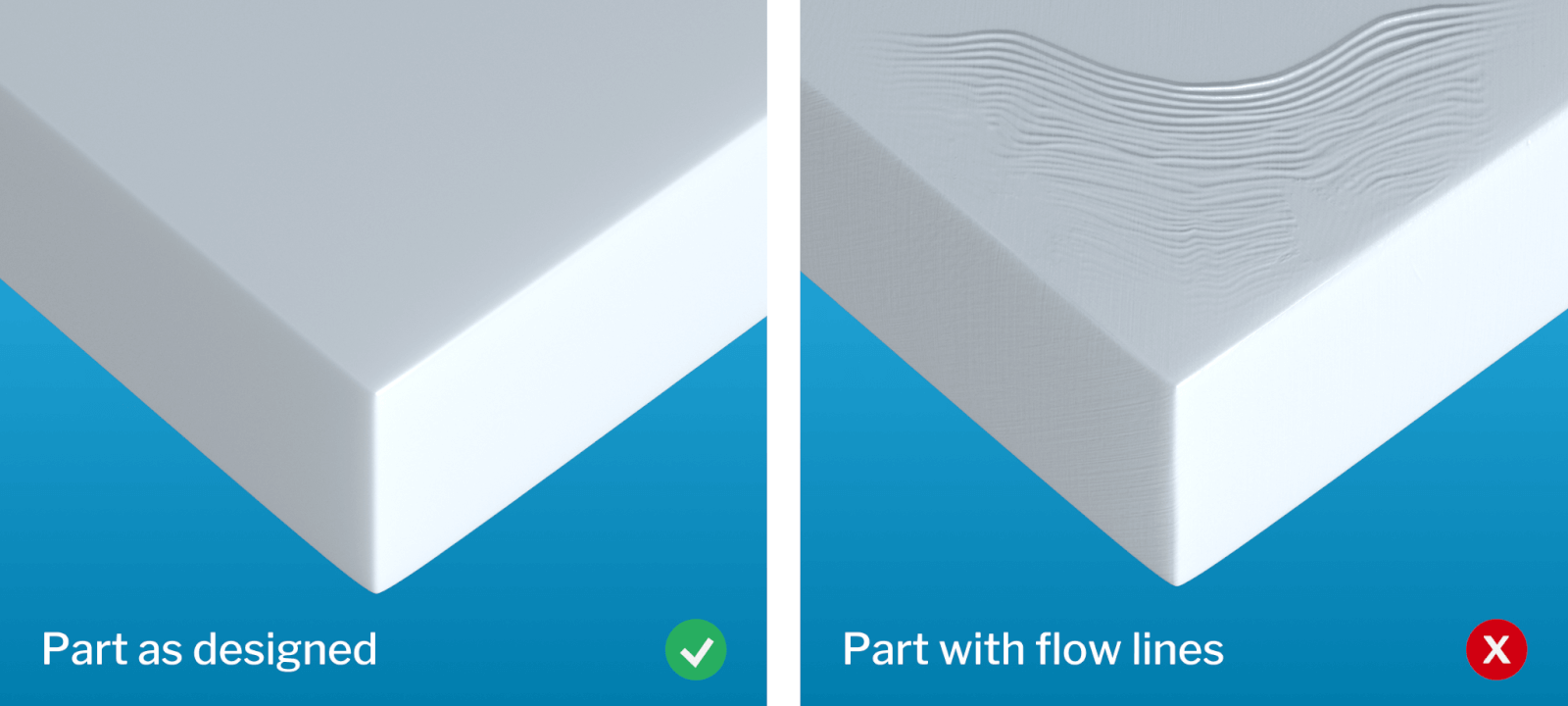

How to avoid injection molding flow lines

Basics of Injection Molding Design

Mold Life Expectancy

HOW TO IMPROVE THE INJECTION MOLD LIFE - Plastic Injection Molding and Mold Maker Manufacturing

Importance of Optimizing Cooling & Venting in Plastic Injection Molding

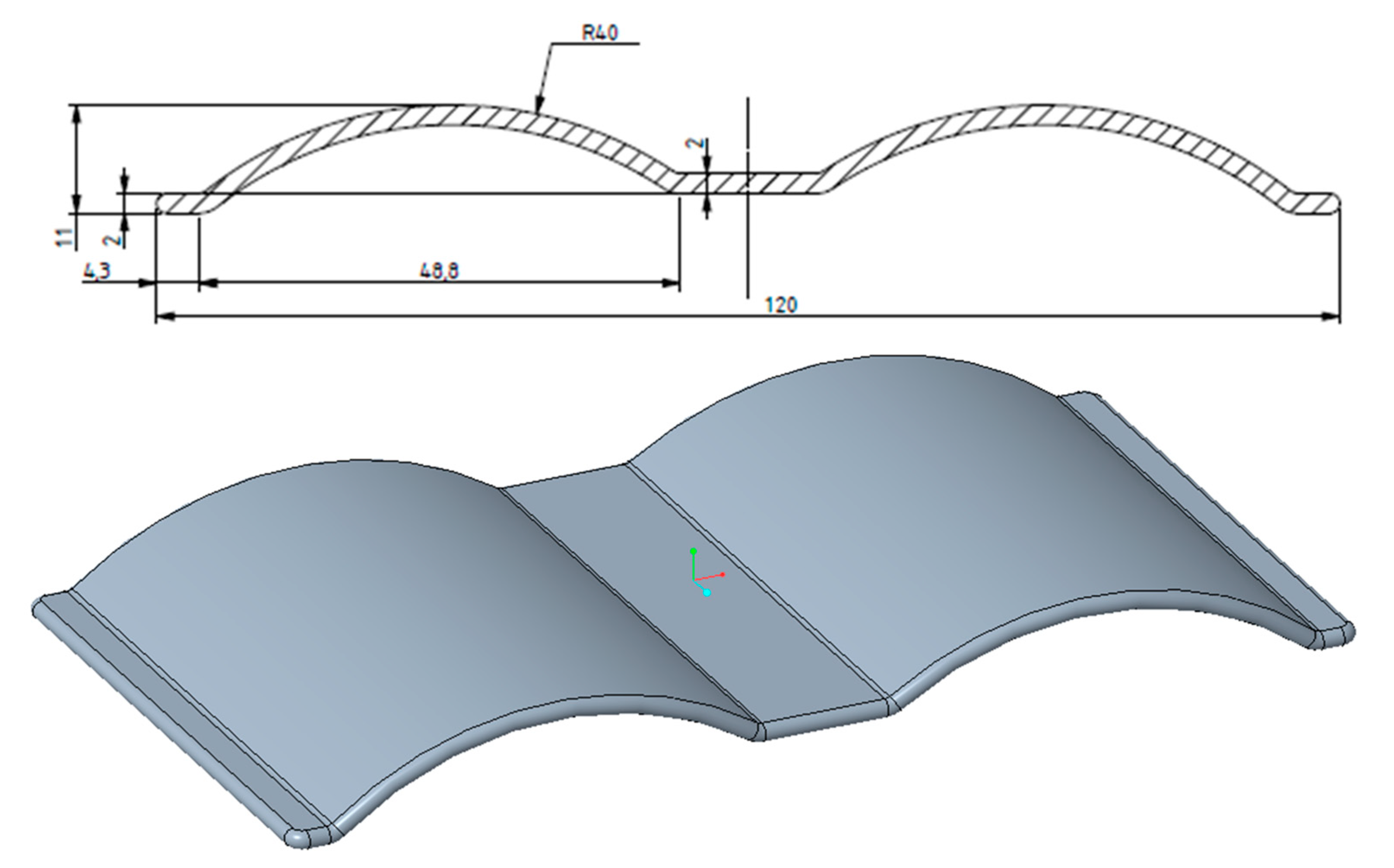

Polymers, Free Full-Text

Injection Molding Defects: Vacuum Voids and Gas Pockets - Midstate Mold

Injection moulding - Wikipedia

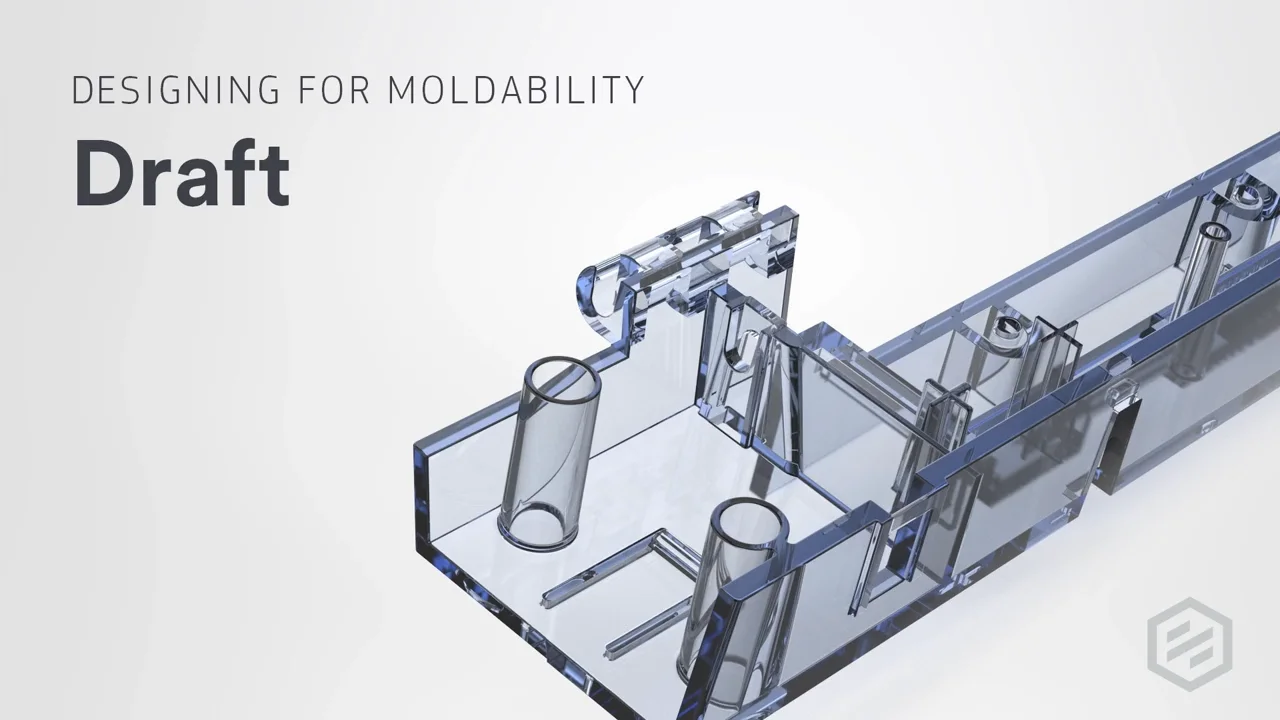

Draft Angle Guidelines for Injection Molding

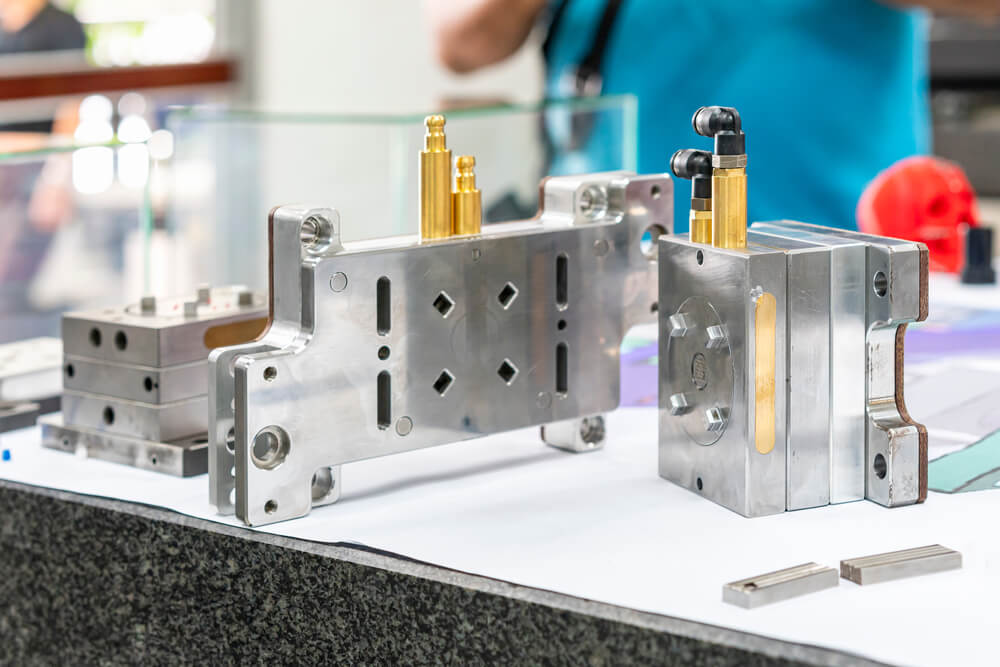

Injection Molding: Mold Design

Determining Vent Depths in Injection Molding

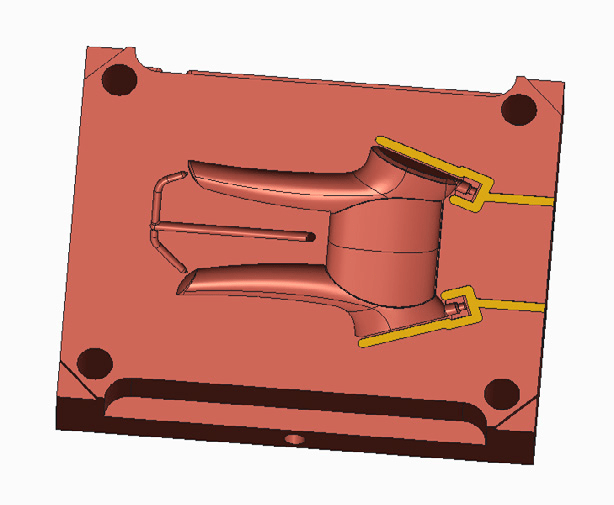

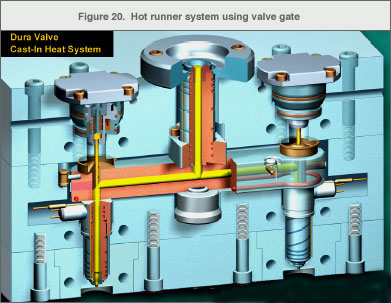

Cooling system and gating design.

Slow cooling relieves internal stresses of molded parts - ACO MOLD CO., LIMITED

Mechanical modifications in the inferior cavity of the mold: air vents

How to Mitigate Short Shots in Plastic Injection Molding?