Sheet Metal Hemming, Hem Types & Processes Explained

4.8 (189) · $ 18.99 · In stock

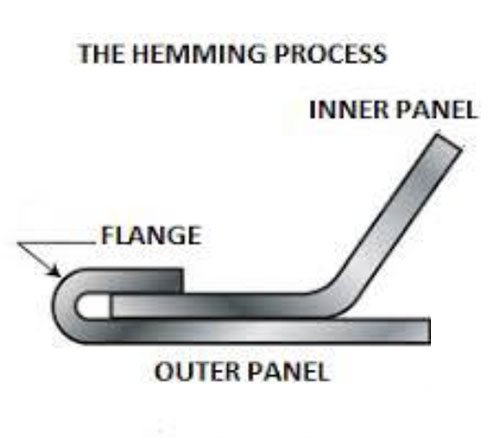

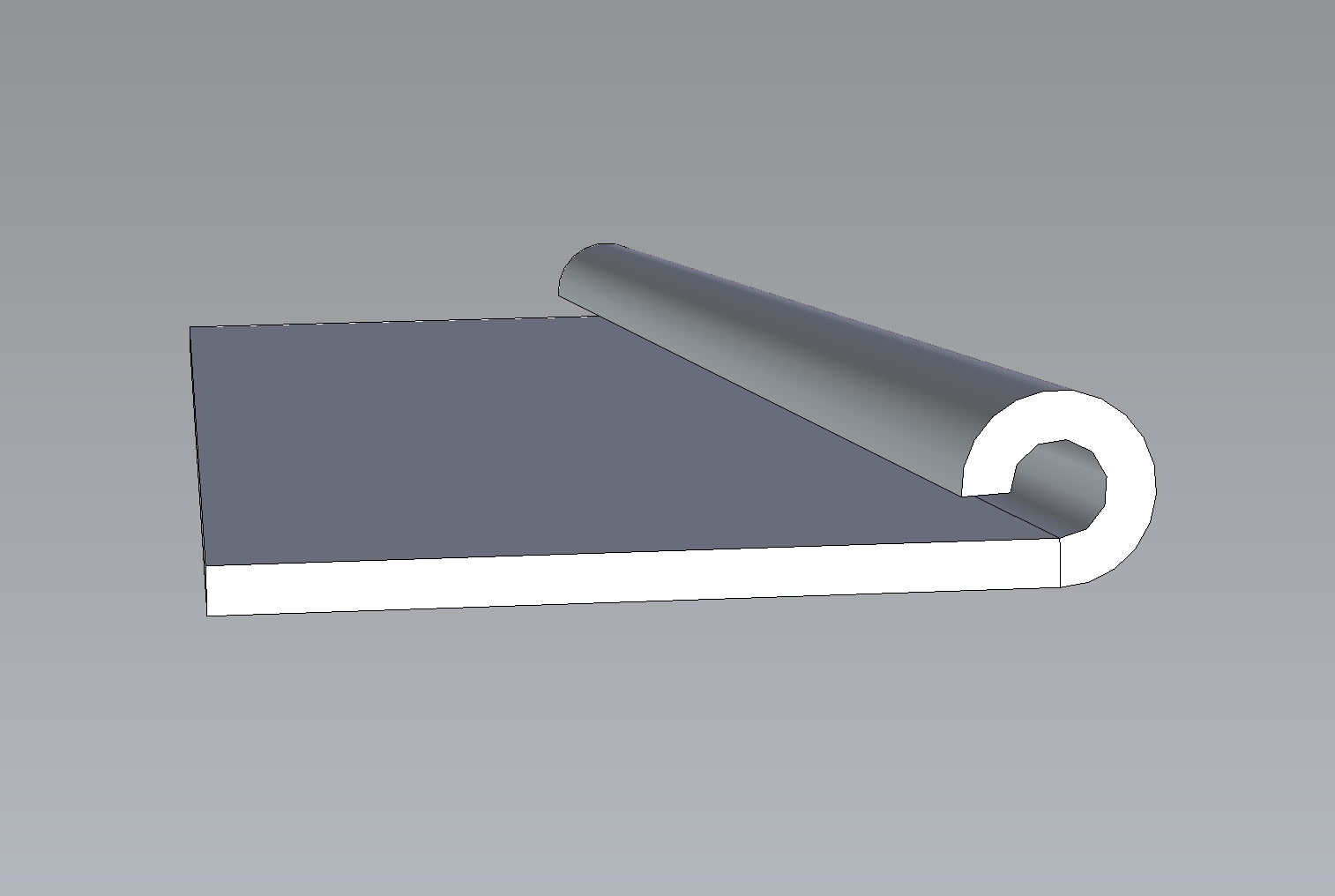

Hemming is a sheet metal forming process where the edge is folded onto itself. Hems make a part more durable and improve its appearance.

Die hemming carried out in 2 steps, manual flattening on a press brake

Hem roll die set, 3 rollers

Roller Hemming offers high flexibility, automotive parts.

Sheet Metal Hemming, Hem Types & Processes Explained

Unit 4 sheet metal operations part 1

Sheet Metal Hemming, Hem Types & Processes Explained

A study on sheet metal hemming process - ScienceDirect

D'source Hemming and Seaming, Sheet Metal Joinery

Sheet metal processes

7 Ways to Improve Sheet Metal Parts

Roller hemming process Download Scientific Diagram

4 Common Types of Sheet Metal Hems (Updated for 2024)

What sheet metal shops wish you knew: Hems, jogs, and forming tools

Sheet Metal Hemming, Hem Types & Processes Explained

Hemming and seaming - Wikipedia

Sheet Metal Fabrication: An introduction to the sheet metal designing