3D Printed Tooling Supports Prototype Foam Seating

4.8 (493) · $ 9.00 · In stock

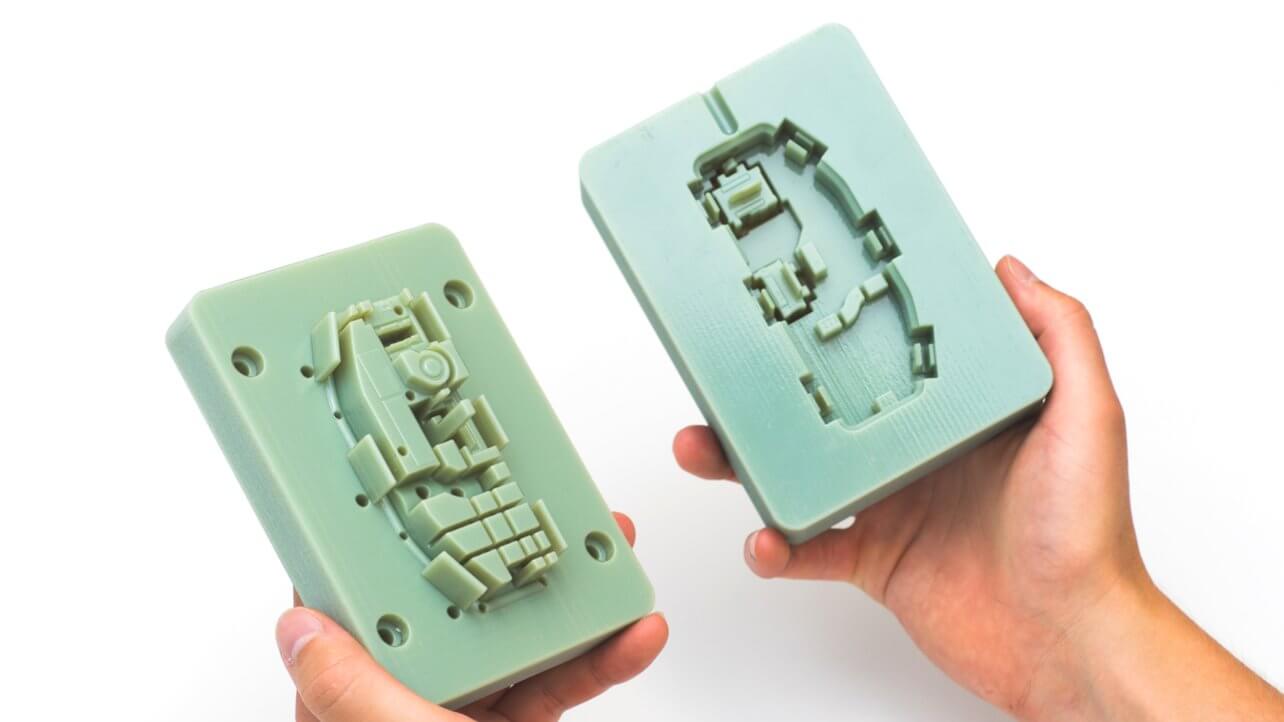

3D printed tools could be a faster, more affordable way to prototype and produce foam parts for automakers and other OEMs.

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

A growing trend: 3D printing of aerospace tooling

4 Ways Augmented Reality and 3D Printing Intersect

Foam - Page 1 of 1 Additive Manufacturing

Home - Catalysis Additive Tooling

Porsche adds comfort and drops weight with new seat design - DEVELOP3D

ExOne Acquires Freshmade 3D Assets

This modular basketball shoe 3D printed in parts for comfort, cushion and traction has a green heart - Yanko Design

How 3D printed tooling can shape the future of prototyping

4 Ways Augmented Reality and 3D Printing Intersect

AM's 2020 Advance: How the Crisis Created Conditions for Additive

/wp-content/uploads/2023/07/concept-brea